Flexible Membrane Sensor

What is the product?

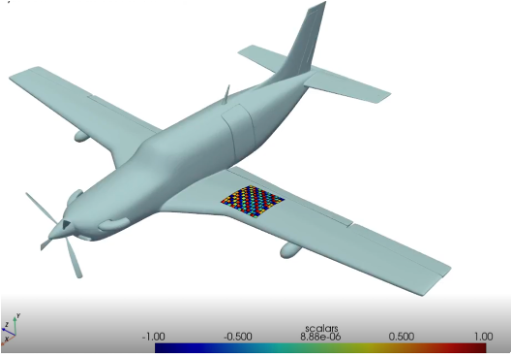

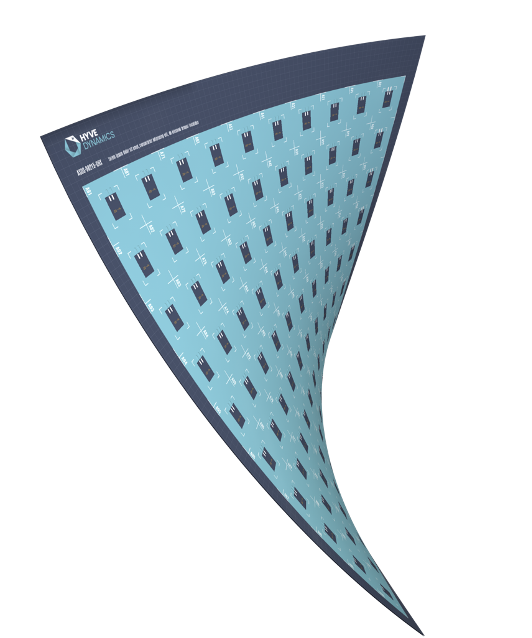

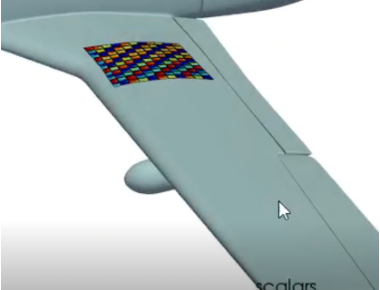

Hyve’s flexible sensor skin replaces pressure taps with thousands of live data points, delivering high-resolution pressure and strain maps in real time—cutting test time, increasing accuracy, and unlocking true surface intelligence.

What is it used for?

Hyve’s sensor skin is used in wind tunnels to capture real-time pressure and strain data, replacing pressure taps, pressure-sensitive paint, and tufting. It enhances CFD validation, accelerates development, and delivers high-resolution insights across complex aerodynamic surfaces in aerospace, automotive and beyond.

Why is it of benefit to industry?

Hyve’s sensor skin gives wind tunnel teams real-time, high-density pressure and strain data without taps or wiring. It cuts setup time, boosts accuracy, and enables faster, more detailed testing—accelerating design cycles and unlocking deeper aerodynamic insights across complex surfaces.

What has it been proven to achieve?

Hyve’s technology has been proven to match the performance of traditional pressure taps while delivering up to 100 times the data density. This enables far more detailed surface mapping, faster iteration, and deeper aerodynamic insight—significantly enhancing test efficiency, CFD validation, and design optimisation.

How can industry test this product or get involved?

Contact the Hyve team at info@hyvedynamics.com

Where can I find out more information?

www.hyvedynamics.com

Who should I contact to open discussions?

simona.blackmore@hyvedynamics.com